Grinding is a processing method of removing excess materials from the workpiece with super abrasives, which can process materials of any hardness. As a traditional machining model, it can obtain high workpiece precision and surface quality, high processing efficiency and low cost. It occupies a very high proportion in the field of advanced manufacturing. Different grinding methods will produce different grinding defects in the application process, and the most influential factor on grinding defects is grinding wheel. This paper describes in detail the defects caused by the specific grinding wheel factors and the corresponding dressing methods, as shown in the table below.

Table 1 Common problems and solutions of grinding wheel in the process of grinding

Grinding is a complex system engineering, and the grinding wheel and grinding process should be correctly selected according to the material characteristics of the workpiece. When there are different grinding defects in the working conditions, the correct dressing method should be adopted, so that the workpieces with good machining quality and high dimensional accuracy can be obtained, so as to improve the production efficiency and reduce the production cost.

CBN/DIA Superabrasive

lmprove grinding efficiency toa new level

PCD Blank

lmprove the comprehensive competitionadvantages of cutting tool manufacturer

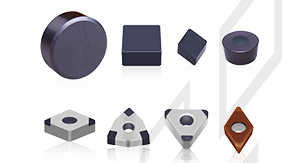

PCBN Insert

Substantially improve cuttingefficiency and tool life

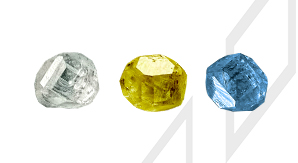

HPHT Lab-grown Diamond

Protecting the environment and creating art and beauty with technology is the tireless pursuit of MDC